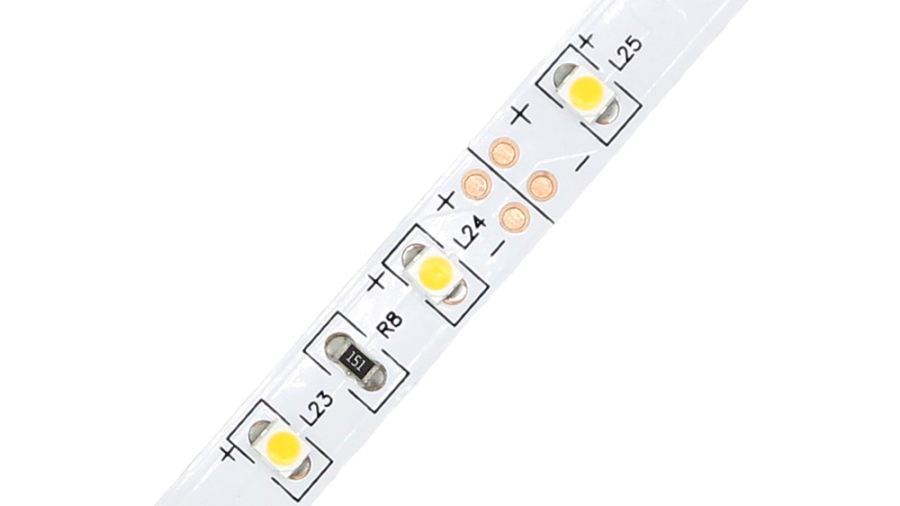

SMD a COB LED Strip Light Beth yw'r gwahaniaeth?

Beth yw'r gwahaniaeth rhwng downlights coB a downlights LED

1. Technoleg wahanol

Mae Leds yn ddyfeisiadau lled-ddargludyddion cyflwr solet sy'n trosi trydan yn olau yn uniongyrchol. Arweiniodd, fel y drydedd genhedlaeth o dechnoleg goleuo ar ôl lamp gwynias a lamp fflwroleuol, mae ganddo nodweddion arbed ynni, diogelu'r amgylchedd, diogelwch a dibynadwyedd.

Mae ffynhonnell golau cob ynghlwm yn uniongyrchol â'r sglodion dan arweiniad cyfradd adlewyrchol uchel o wyneb drych o effeithlonrwydd ffotosynthetig uchel o dechnoleg ffynhonnell golau integredig swbstrad metel, y dechnoleg i ddileu'r cysyniad o stentiau, platio electroless, sodro reflow, Proses yr UDRh, felly y broses i leihau bron i draean, arbedion cost o draean, termau poblogaidd yn fwy datblygedig na goleuadau dan arweiniad, and the lamp that shield an eye.

2. Different lighting

Led lights can save energy, diogelu'r amgylchedd, no strobotron no ULTRAVIOLET radiation, the disadvantage is blue light harm. Cob lamp high color rendering, light color close to natural color, no stroboscopic, no glare, no electromagnetic radiation, no ultraviolet radiation, infrared radiation, can protect eyes and skin.

Cob advantages

1. Advantages of production and manufacturing efficiency

The production process of COB packaging is basically the same as that of traditional SMD production process. The efficiency of COB packaging is basically the same as that of SMD packaging in the process of solid crystal and welding line. Fodd bynnag, the efficiency of COB packaging is much higher than that of SMD products in dispensing, separation, splitting and packaging.

The labor and manufacturing cost of traditional SMD packaging is about 15% of the material cost, while the labor and manufacturing cost of COB packaging is about 10% of the material cost. With COB packaging, the labor and manufacturing cost can be saved by 5%.

2, low thermal resistance advantage

The system thermal resistance of traditional SMD packaging application is: chip – solid crystal gel – solder joint – solder paste – copper foil – insulation layer – aluminum material. COB package system thermal resistance: chip – solid crystal gel – aluminum. The system thermal resistance of COB package is much lower than that of traditional SMD package, which greatly improves the life of LED.

. 3, light quality advantage

Traditional SMD packages attach multiple discrete components to THE PCB in the form of patches to form light source components for LED applications, which has problems of spot light, glare and glow-out. COB packaging is integrated packaging, is a surface light source, the advantage is a large Angle of view and easy to adjust, reduce the loss of light refraction

Daw'r canlyniadau cyfieithu uchod o gymhariaeth brawddeg wrth frawddeg Youdao Neural Network Translation (YNMT).

Ychwanegu Sylw