Kuidas paigaldada COB LED ribavalgusti?

What is the installation method of LED car light strip

Second step: then you can take electricity on the lamp holder of the width lamp, but to distinguish the positive and negative poles, it is best to use the electric pen quantity, the bright is the positive pole, if you want to improve the life, you can series an ohm resistor on the lamp set to limit the current, to prevent the lamp set by the mutation of high voltage breakdown.

Samm 3: Article LED car light installation is mounted on the front bumper can intake grid, even the good line, the use of hot melt adhesive sealing in waterproof and wheels to each tire off, put article LED auto light to the part of the brake pads, there should be a place to fixed, looking is what car, along with the parts of the site, as long as can be fixed in a circle, very simple, Can get online first look for the structure chart of your car, so be sure of a few.

Samm 4: Electricity pen to find small car lights line, shut off the small lights, pencil is not bright, open the small light electric pen on, finding the line after the main article LED car light the connected and the negative electrode wire can meet the headlight assembly negative line also can directly take iron, it doesn’t matter, wrapped in electrical tape or heat shrinkable tube, to mend junctions, fixed good article LED car light, complete, The small light line is in the headlamp assembly wiring harness, open the boot cover and look behind the headlamp.

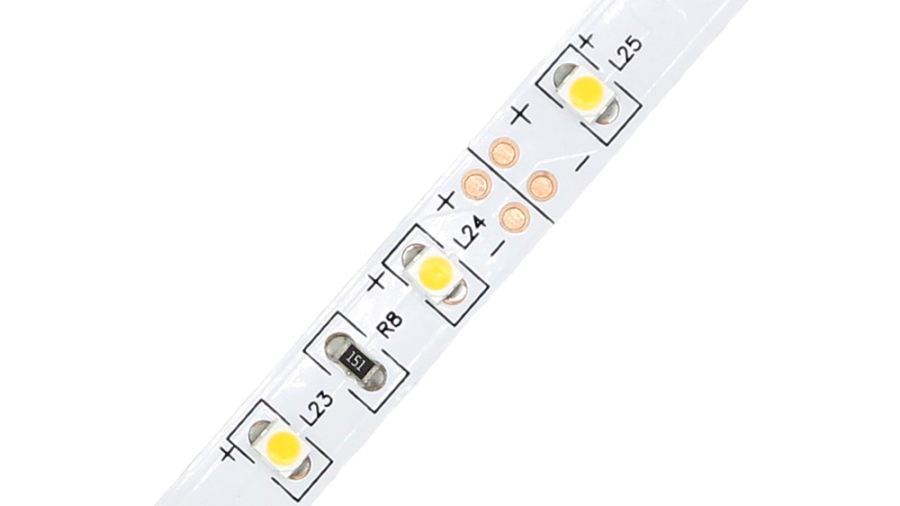

Led lamp wiring diagram

The steps for connecting LED lights are as follows:

1, first install the current limiting resistor on the negative pole of the power line.

2, then separate the positive and negative lines of the LED lamp belt.

3. Remove the positive pole line of the LED lamp belt with a peeling device.

4, stripped LED lamp positive line. As shown in the figure below.

5. Connect the negative pole line of the power supply with the positive pole line of the LED lamp strip.

6. Then connect the negative lead of THE LED with the current limiting resistor.

7. After completing the above steps, the wiring of the LED lamp is completed.

8. Lõpuks, open the LED light switch for testing, and find that the LED light is on and the wiring process is correct.

Ülaltoodud tõlketulemused pärinevad Youdao Neural Network Translationi (YNMT) lause-lausete võrdlusest