Cara pemasangan lampu strip LED COB?

What is the installation method of LED car light strip

Second step: then you can take electricity on the lamp holder of the width lamp, but to distinguish the positive and negative poles, it is best to use the electric pen quantity, the bright is the positive pole, if you want to improve the life, you can series an ohm resistor on the lamp set to limit the current, to prevent the lamp set by the mutation of high voltage breakdown.

Melangkah 3: Article LED car light installation is mounted on the front bumper can intake grid, even the good line, the use of hot melt adhesive sealing in waterproof and wheels to each tire off, letakkan lampu otomatis LED artikel pada bagian bantalan rem, harus ada tempat untuk memperbaikinya, mencari adalah mobil apa, beserta bagian-bagian situsnya, selama bisa diperbaiki dalam lingkaran, sangat sederhana, Bisa online dulu untuk melihat bagan struktur mobil Anda, jadi pastikan beberapa.

Melangkah 4: Pena listrik untuk mencari garis lampu mobil kecil, matikan lampu kecil, pensil tidak cerah, buka pena listrik kecil yang menyala, menemukan garis setelah artikel utama Lampu mobil LED terhubung dan kawat elektroda negatif dapat memenuhi garis negatif perakitan lampu depan juga dapat langsung mengambil besi, itu tidak masalah, dibungkus dengan pita listrik atau tabung yang dapat menyusut panas, untuk memperbaiki persimpangan, memperbaiki artikel bagus lampu mobil LED, menyelesaikan, Garis lampu kecil ada di rangkaian kabel rakitan lampu depan, buka penutup bagasi dan lihat ke belakang lampu depan.

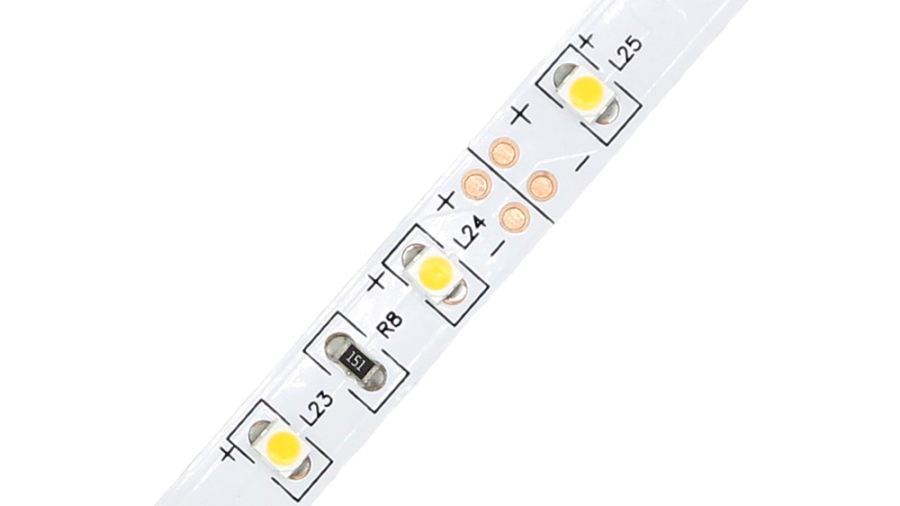

Diagram pengkabelan lampu led

Langkah-langkah penyambungan lampu LED adalah sebagai berikut:

1, pertama pasang resistor pembatas arus pada kutub negatif saluran listrik.

2, kemudian pisahkan garis positif dan negatif dari sabuk lampu LED.

3. Lepaskan garis kutub positif sabuk lampu LED dengan alat pengupas.

4, garis positif lampu LED yang dilucuti. Seperti yang ditunjukkan pada gambar di bawah ini.

5. Hubungkan garis kutub negatif catu daya dengan garis kutub positif pada strip lampu LED.

6. Kemudian sambungkan kabel negatif LED dengan resistor pembatas arus.

7. Setelah menyelesaikan langkah-langkah di atas, pengkabelan lampu LED selesai.

8. Akhirnya, buka sakelar lampu LED untuk pengujian, dan temukan bahwa lampu LED menyala dan proses pengkabelan sudah benar.

Hasil terjemahan di atas adalah dari perbandingan kalimat demi kalimat Youdao Neural Network Translation (YNMT).