How to install the COB LED strip light?

What is the installation method of LED car light strip

Second step: then you can take electricity on the lamp holder of the width lamp, but to distinguish the positive and negative poles, it is best to use the electric pen quantity, the bright is the positive pole, if you want to improve the life, you can series an ohm resistor on the lamp set to limit the current, to prevent the lamp set by the mutation of high voltage breakdown.

Solis 3: Article LED car light installation is mounted on the front bumper can intake grid, even the good line, the use of hot melt adhesive sealing in waterproof and wheels to each tire off, pielieciet izstrādājuma LED auto gaismu bremžu kluču daļai, jābūt vietai, kur salabot, izskatās ir kāda mašīna, kopā ar vietnes daļām, tik ilgi, cik vien var fiksēt riņķī, ļoti vienkārši, Varat tiešsaistē vispirms meklēt savas automašīnas struktūras diagrammu, tāpēc pārliecinieties par dažiem.

Solis 4: Elektrības pildspalva, lai atrastu mazu automašīnu lukturu līniju, izslēdziet mazās gaismas, zīmulis nav spilgts, atveriet mazo gaismas elektrisko pildspalvu, līnijas atrašana pēc galvenā izstrādājuma LED automašīnas apgaismojums savienotais un negatīvā elektroda vads var saskarties ar lukturu montāžas negatīvo līniju, arī var tieši uzņemt dzelzi, tam nav nozīmes, ietin elektriskajā lentē vai termosarūkošā caurulē, salabot krustojumus, fiksēts labs raksts LED auto gaisma, pabeigt, Mazā gaismas līnija atrodas galvenā luktura montāžas vadu instalācijā, open the boot cover and look behind the headlamp.

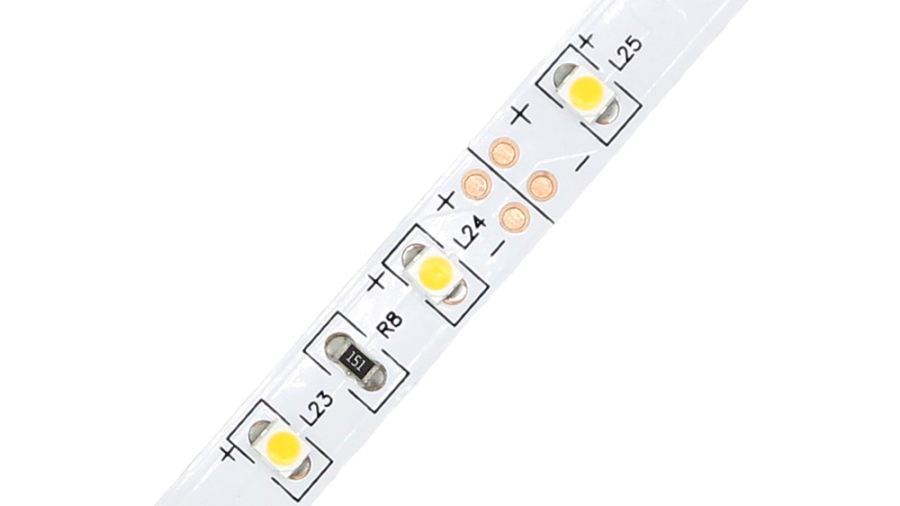

Led lamp wiring diagram

The steps for connecting LED lights are as follows:

1, first install the current limiting resistor on the negative pole of the power line.

2, then separate the positive and negative lines of the LED lamp belt.

3. Remove the positive pole line of the LED lamp belt with a peeling device.

4, stripped LED lamp positive line. As shown in the figure below.

5. Connect the negative pole line of the power supply with the positive pole line of the LED lamp strip.

6. Then connect the negative lead of THE LED with the current limiting resistor.

7. After completing the above steps, the wiring of the LED lamp is completed.

8. Beidzot, open the LED light switch for testing, and find that the LED light is on and the wiring process is correct.

Iepriekš minētie tulkošanas rezultāti iegūti no Youdao neironu tīkla tulkošanas (YNMT) teikumu pa teikumam salīdzinājuma.