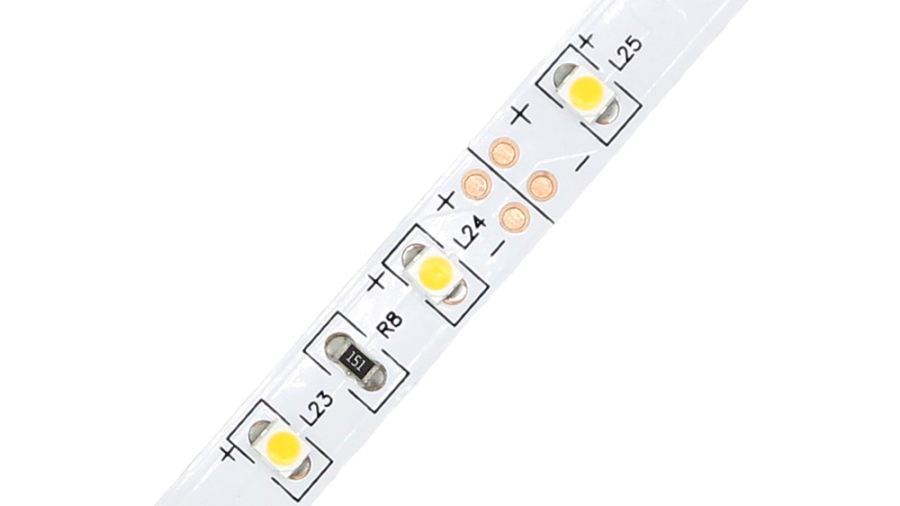

SMD un COB LED sloksnes gaisma Kāda ir atšķirība?

What is the difference between coB downlights and LED downlights

1. Different technology

Leds are solid-state semiconductor devices that convert electricity directly into light. Led, as the third generation of lighting technology after incandescent lamp and fluorescent lamp, has the characteristics of energy saving, environmental protection, safety and reliability.

Cob light source is directly attached to the led chip high reflective rate of mirror surface of high photosynthetic efficiency of metal substrate integrated light source technology, the technology to eliminate the concept of stents, electroless plating, reflow soldering, SMT process, tāpēc process jāsamazina gandrīz par trešdaļu, izmaksu ietaupījums par trešdaļu, populāri termini ir uzlaboti nekā LED gaismas, un lukturi, kas pasargā aci.

2. Dažāds apgaismojums

Led gaismas var ietaupīt enerģiju, environmental protection, nav strobotrona nav ULTRAVIOLĒTA starojuma, trūkums ir zilās gaismas kaitējums. Vālītes lampa ar augstu krāsu atveidi, gaiša krāsa tuvu dabiskajai krāsai, nav stroboskopiska, nav atspīdumu, nav elektromagnētiskā starojuma, nav ultravioletā starojuma, infrasarkanais starojums, var aizsargāt acis un ādu.

Vālītes priekšrocības

1. Ražošanas priekšrocības un ražošanas efektivitāte

COB iepakojuma ražošanas process būtībā ir tāds pats kā tradicionālajam SMD ražošanas procesam. COB iepakojuma efektivitāte būtībā ir tāda pati kā SMD iepakojuma efektivitāte cieto kristālu un metināšanas līnijas procesā. Tomēr, the efficiency of COB packaging is much higher than that of SMD products in dispensing, separation, splitting and packaging.

The labor and manufacturing cost of traditional SMD packaging is about 15% of the material cost, while the labor and manufacturing cost of COB packaging is about 10% of the material cost. With COB packaging, the labor and manufacturing cost can be saved by 5%.

2, low thermal resistance advantage

The system thermal resistance of traditional SMD packaging application is: chip – solid crystal gel – solder joint – solder paste – copper foil – insulation layer – aluminum material. COB package system thermal resistance: chip – solid crystal gel – aluminum. The system thermal resistance of COB package is much lower than that of traditional SMD package, which greatly improves the life of LED.

. 3, light quality advantage

Traditional SMD packages attach multiple discrete components to THE PCB in the form of patches to form light source components for LED applications, which has problems of spot light, glare and glow-out. COB packaging is integrated packaging, is a surface light source, the advantage is a large Angle of view and easy to adjust, reduce the loss of light refraction

Iepriekš minētie tulkošanas rezultāti iegūti no Youdao neironu tīkla tulkošanas (YNMT) teikumu pa teikumam salīdzinājuma.

Pievieno komentāru