Slik installerer du COB LED stripelys?

Hva er installasjonsmetoden for LED-billysstripe

Andre trinn: da kan du ta strøm på lampeholderen til breddelampen, men for å skille de positive og negative polene, det er best å bruke den elektriske pennen, det lyse er den positive polen, hvis du ønsker å forbedre livet, du kan serie en ohm-motstand på lampesettet for å begrense strømmen, for å forhindre at lampen settes av mutasjonen av høyspenningssammenbrudd.

Steg 3: Artikkel LED billys installasjon er montert på frontstøtfangeren kan inntaksgitteret, selv den gode linjen, bruk av smeltelim forsegling i vanntett og hjul til hvert dekk av, sette artikkelen LED autolys til delen av bremseklossene, det bør være et sted å fikse, ser er hvilken bil, sammen med delene av nettstedet, så lenge som kan festes i en sirkel, veldig enkelt, Kan komme på nettet først se etter strukturdiagrammet til bilen din, så vær sikker på noen få.

Steg 4: Elektrisitet penn for å finne små bil lys linje, slå av de små lysene, blyanten er ikke lys, åpne den lille lys elektriske pennen på, finne linjen etter hovedartikkelen LED-billys den tilkoblede og den negative elektrodeledningen kan møte frontlyktens negative linje kan også direkte ta jern, det spiller ingen rolle, pakket inn i elektrisk tape eller varmekrympbart rør, å reparere veikryss, fast god artikkel LED billys, fullstendig, Den lille lyslinjen er i ledningsnettet til frontlykten, åpne bagasjeromsdekselet og se bak hodelykten.

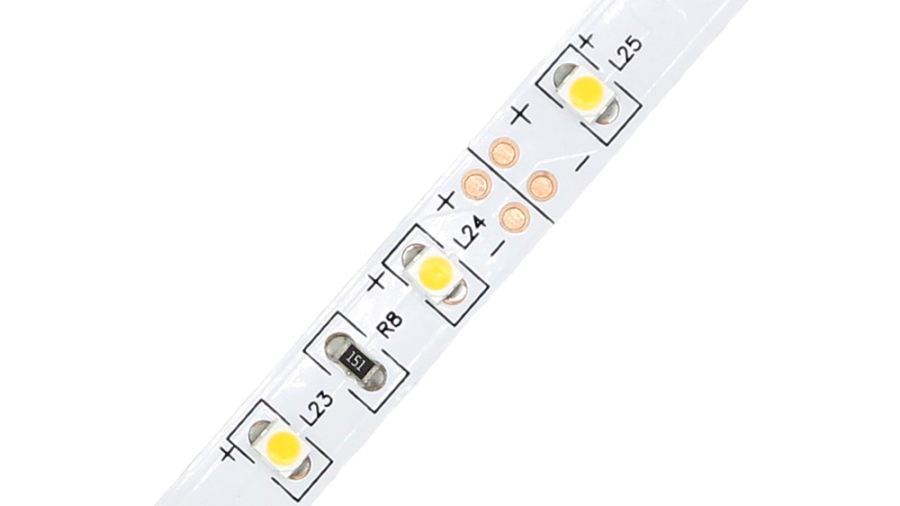

Led-lampe koblingsskjema

Trinnene for å koble til LED-lys er som følger:

1, installer først strømbegrensningsmotstanden på den negative polen til kraftledningen.

2, skille deretter de positive og negative linjene til LED-lampebeltet.

3. Fjern den positive pollinjen til LED-lampebeltet med en skrelleanordning.

4, strippet LED-lampe positiv linje. Som vist i figuren nedenfor.

5. Koble den negative pollinjen til strømforsyningen med den positive pollinjen til LED-lampestripen.

6. Koble deretter den negative ledningen til LED-en med strømbegrensningsmotstanden.

7. Etter å ha fullført trinnene ovenfor, ledningen til LED-lampen er fullført.

8. Endelig, åpne LED-lysbryteren for testing, og finn ut at LED-lyset er på og at ledningsprosessen er korrekt.

Oversettelsesresultatene ovenfor kommer fra Youdao Neural Network Translation (YNMT) setning-for-setning-sammenligning.