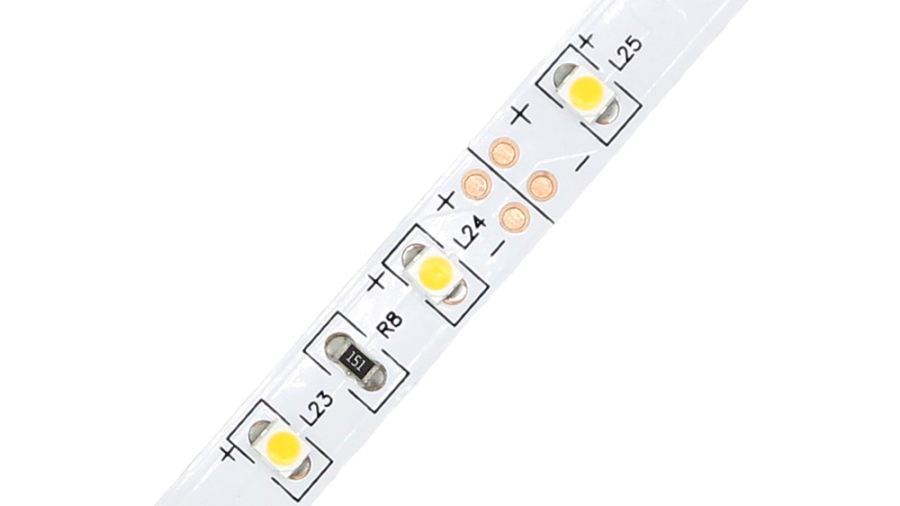

SMD and COB LED Strip Light What is the difference?

What is the difference between coB downlights and LED downlights

1. Different technology

Leds are solid-state semiconductor devices that convert electricity directly into light. Led, as the third generation of lighting technology after incandescent lamp and fluorescent lamp, has the characteristics of energy saving, environmental protection, safety and reliability.

Cob light source is directly attached to the led chip high reflective rate of mirror surface of high photosynthetic efficiency of metal substrate integrated light source technology, the technology to eliminate the concept of stents, electroless plating, reflow soldering, SMT process, so the process to reduce by almost a third, cost savings by a third, popular terms is more advanced than led lights, e a lâmpada que protege um olho.

2. Iluminação diferente

Luzes LED podem economizar energia, environmental protection, sem estrobotron sem radiação ULTRAVIOLETA, a desvantagem são os danos causados pela luz azul. Renderização de alta cor da lâmpada Cob, cor clara próxima da cor natural, sem estroboscópico, sem brilho, sem radiação eletromagnética, sem radiação ultravioleta, radiação infra-vermelha, pode proteger os olhos e a pele.

Vantagens da espiga

1. Vantagens da eficiência de produção e fabricação

O processo de produção das embalagens COB é basicamente o mesmo do processo de produção SMD tradicional. A eficiência da embalagem COB é basicamente a mesma da embalagem SMD no processo de cristal sólido e linha de soldagem. No entanto, a eficiência das embalagens COB é muito maior do que a dos produtos SMD na distribuição, separação, divisão e embalagem.

The labor and manufacturing cost of traditional SMD packaging is about 15% of the material cost, while the labor and manufacturing cost of COB packaging is about 10% of the material cost. With COB packaging, the labor and manufacturing cost can be saved by 5%.

2, low thermal resistance advantage

The system thermal resistance of traditional SMD packaging application is: chip – solid crystal gel – solder joint – solder paste – copper foil – insulation layer – aluminum material. COB package system thermal resistance: chip – solid crystal gel – aluminum. The system thermal resistance of COB package is much lower than that of traditional SMD package, which greatly improves the life of LED.

. 3, light quality advantage

Traditional SMD packages attach multiple discrete components to THE PCB in the form of patches to form light source components for LED applications, which has problems of spot light, glare and glow-out. COB packaging is integrated packaging, is a surface light source, the advantage is a large Angle of view and easy to adjust, reduce the loss of light refraction

Os resultados da tradução acima são da comparação frase por frase do Youdao Neural Network Translation (YNMT)

Adicione um comentário