COB LED 燈條有幾個 LED?

How many beads do LED lights have in general?

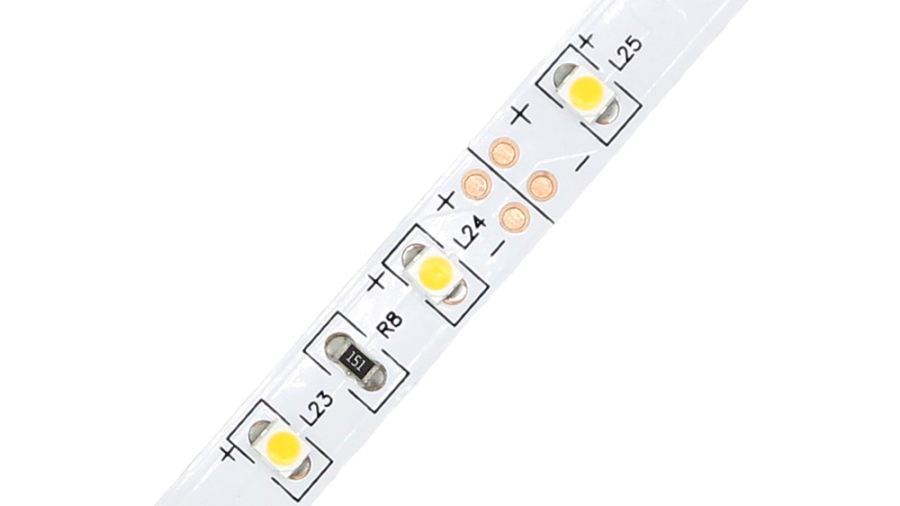

Mainly about the traditional lamp belt, the number of commonly used lamp beads are: 60 beads/meters, beads/meters, beads/meters, beads/meters!

The more beads, the closer the arrangement between the beads, the brighter the lamp belt.

If your home lamp belt is hidden installation, you can choose less beads, if it is an open lamp belt, it is recommended to use the lamp groove, and choose at least one meter of light, so that the light effect will be more ideal. And the lamp belt also has single row, double row of points.

Led soft light bar Specifications Difference between LED soft light bar and LED hard light bar

Led soft strip is a relatively advanced lighting lighting in the lighting industry at present. Led soft strip is mainly based on the flexible circuit board made of polyimide PI substrate as the carrier, and is installed into the high-brightness LED emitter chip through series and parallel circuit design, and then connected to the power supply to control the lighting effect. And LED soft light strip is also a kind of LED lamp belt. Led soft strip his characteristics are also very obvious, such as flexible circuit board, good stability, very low power consumption, 高效率, and the length can also be controlled by itself. So LED soft strip is widely used in many industries.

Led soft strip specifications

According to the luminous color, there are often monochrome bright light belt, monochrome dark light belt, three-color light belt, colorful light belt;

According to the size specifications are often *, *, *8毫米, *7毫米, *6毫米, *5毫米, *8毫米, *6毫米, *5毫米, *4mm and other types;

According to the overall packaging classification: waterproof type, bare type;

According to the circuit board surface process classification: OSP oxidation resistance type, gold sink process type;

According to the circuit board other process classification: large area sensitive white oil type, large area hot solid white oil type, large area sensitive black oil type, large area hot solid black oil type.

FlexLightBar. This is the English name of LED soft light strip, which means flexible light strip. And Chinese LED soft light strip is the same thing, but the name is different.

Led soft strip price

Often with the flexible circuit board made of polyimide PI substrate as the carrier, through the series and parallel circuit design of high brightness LED luminescent chip, with the connection of power supply and light emitting program controller to achieve a variety of dazzling lighting effects of LED lamp belt, called LED soft strip.

Thermal conductivity double-sided tape LED light strip: ¥11/ m (price source network, for reference only)

One meter 54 lamp RGB full color running horse: ¥47/ m (price source network, for reference only)

Patch LED soft strip: ¥22/ meter (price source network, for reference only)

Drip sleeve LED soft light bar: ¥14.6/ m (price source network, for reference only)

Shenzhen spot hot soft light bar: ¥8/ m (price source network, for reference only)

LED soft light strip and LED hard light strip difference

1, LED hard strip is made of PCB hard board assembly circuit board, LED useful patch LED assembly, also useful direct plug LED assembly, depending on the need for different components. The advantages of hard strip are relatively easy to fix, processing and installation are more convenient; The disadvantage is that it cannot be bent at will and is not suitable for irregular places. There are 60 LED and 72 LED patches for hard lamp strips.

2, the flexible LED lamp belt is made of FPC as the assembly circuit board, with the SMT LED assembly, so that the thickness of the product is only the thickness of a coin, does not take up space; The general specifications are 30 引領, 60 引領, 引領, 等等, different users have different specifications. And can be cut at will, can also be arbitrarily extended and light is not affected. FPC is a soft material that can be bent, folded and wound at will, and can be moved and expanded in three dimensions without breaking. It is suitable for irregular places and narrow Spaces, and can be arbitrarily bent and wound, suitable for any combination of patterns in advertising decoration.

Led soft light strip is a very common light source in our life, in advertising signs, three-dimensional luminous words, advertising light box, car taillights, headlights, special clothing, mobile phone background light and signal sensor light are used. And LED soft light strip can be divided into monochrome light belt, monochrome dark light belt, three-color light belt, colorful light belt, and he is also very convenient to install, but when you install it, we must do a good job of waterproof work, and the lamps and lanterns in the installation to reinforce, the interface should also do a good job of waterproof work. In addition, we must pay attention to his safety performance when we choose and buy.

以上翻譯結果來自有道神經網路翻譯(YNMT)逐句對照