COB LED灯条中有多少颗LED?

LED灯一般有多少颗灯珠?

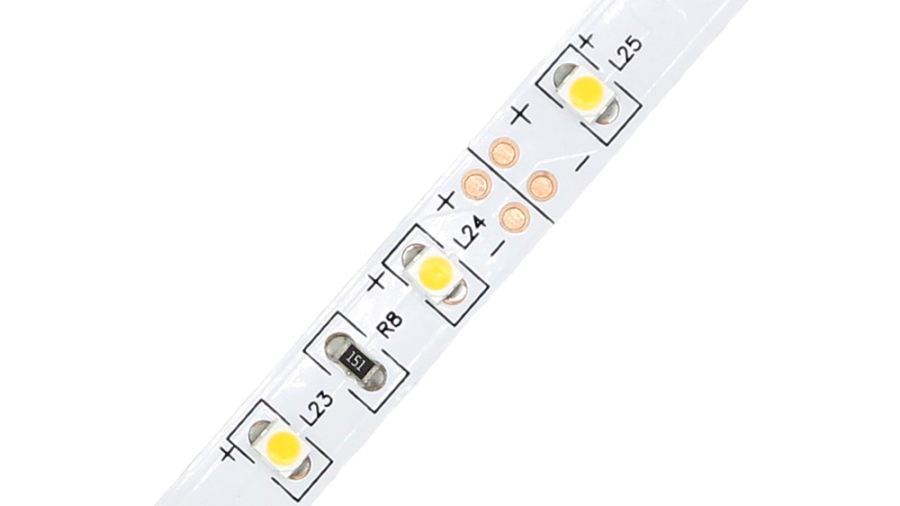

主要是关于传统灯带, 常用灯珠数量有: 60 珠/米, 珠/米, 珠/米, 珠/米!

珠子越多, 珠子之间的排列越紧密, 灯带越亮.

如果你家的灯带是隐藏式安装的, 你可以选择较少的珠子, 如果是开放式灯带, 建议使用灯槽, 并选择至少一米的光线, 这样灯光效果会更加理想。而且灯带也有单排的, 双排点.

LED软灯条规格 LED软灯条和LED硬灯条的区别

LED软灯条是目前照明行业中比较先进的照明灯具. Led soft strip is mainly based on the flexible circuit board made of polyimide PI substrate as the carrier, and is installed into the high-brightness LED emitter chip through series and parallel circuit design, and then connected to the power supply to control the lighting effect. And LED soft light strip is also a kind of LED lamp belt. Led soft strip his characteristics are also very obvious, such as flexible circuit board, good stability, very low power consumption, 高效率, and the length can also be controlled by itself. So LED soft strip is widely used in many industries.

Led soft strip specifications

According to the luminous color, there are often monochrome bright light belt, monochrome dark light belt, three-color light belt, colorful light belt;

According to the size specifications are often *, *, *8毫米, *7毫米, *6毫米, *5毫米, *8毫米, *6毫米, *5毫米, *4mm and other types;

According to the overall packaging classification: waterproof type, bare type;

According to the circuit board surface process classification: OSP oxidation resistance type, gold sink process type;

According to the circuit board other process classification: large area sensitive white oil type, large area hot solid white oil type, large area sensitive black oil type, large area hot solid black oil type.

FlexLightBar. This is the English name of LED soft light strip, which means flexible light strip. And Chinese LED soft light strip is the same thing, but the name is different.

Led soft strip price

Often with the flexible circuit board made of polyimide PI substrate as the carrier, through the series and parallel circuit design of high brightness LED luminescent chip, 配合电源和发光程序控制器的连接,实现LED灯带的多种炫丽灯光效果, 称为LED软灯条.

导热双面胶带 LED灯条: 11元/米 (价格来源网, 仅供参考)

一米 54 RGB全彩跑马灯: 47元/平方米 (价格来源网, 仅供参考)

贴片LED软灯带: 22元/米 (价格来源网, 仅供参考)

滴水套LED软灯条: 14.6元/米 (价格来源网, 仅供参考)

深圳现货热销软灯条: 8元/米 (价格来源网, 仅供参考)

LED软灯条和LED硬灯条的区别

1, LED硬灯条是由PCB硬板组装电路板制成, LED有用贴片LED组装, 也有用直插 LED 组件, 根据不同组件的需要。硬条的优点是比较容易固定, 加工安装更方便; 缺点是不能随意弯曲,不适合不规则的地方。有 60 LED 和 72 硬灯条LED贴片.

2, 柔性LED灯带采用FPC作为组装电路板, 与 SMT LED 组件, 使产品的厚度只有硬币的厚度, 不占用空间; 一般规格为 30 引领, 60 引领, 引领, 等等, 不同的用户有不同的规格。并且可以随意剪裁, 也可任意延长且光线不受影响。 FPC是一种软质材料,可以弯曲, 随意折叠、缠绕, 并且可以在三个维度上移动和扩展而不破裂。适用于不规则场所及狭窄空间, 并且可以任意弯曲和缠绕, 适合广告装饰中图案的任意组合.

LED软灯条是我们生活中非常常见的光源, 在广告招牌中, 立体发光字, 广告灯箱, 汽车尾灯, 车头灯, 特殊服装, 使用手机背景灯和信号感应灯。而LED软灯带又可分为单色灯带, monochrome dark light belt, three-color light belt, colorful light belt, 而且他安装起来也很方便, 但是当你安装它时, 我们一定要做好防水工作, 并对安装中的灯具进行加固, 接口处也要做好防水工作。此外, 我们在选购的时候一定要注意他的安全性能。

以上翻译结果来自有道神经网络翻译(YNMT)逐句对照